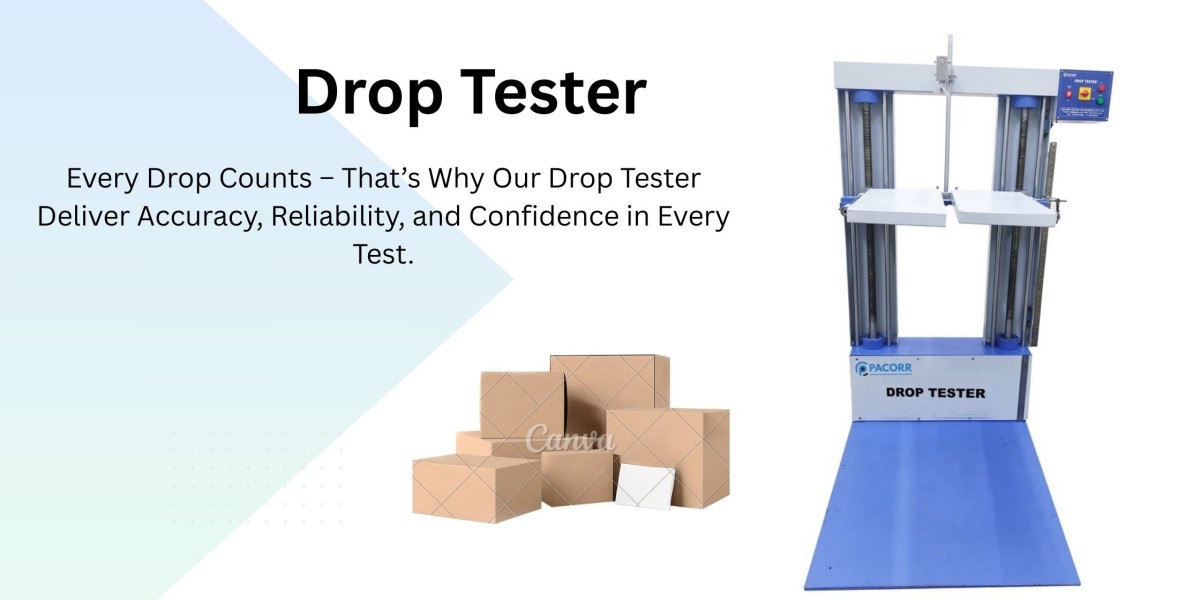

At Pacorr.com, we specialize in providing high-performance Drop Tester that help businesses across various sectors assess the durability and safety of their packaging and products. These precision instruments allow manufacturers to simulate real-world drop scenarios, ensuring that their goods arrive in perfect condition, no matter the distance or handling conditions.

What is a Drop Tester?

A drop tester is a specialized instrument used to test how a product or its packaging behaves when dropped from a specific height. It simulates the impact of accidental drops that can occur during shipping, handling, or daily usage. The device helps evaluate the structural integrity of packaging materials such as cardboard boxes, plastic containers, and even the products inside.

By analyzing the effects of drops from different angles and heights, manufacturers can gain valuable insights into how to improve product designs, strengthen packaging, and reduce the risk of damage during transit.

Why Drop Testing is Crucial for Modern Industries

1. Product Protection

A damaged product can result in customer dissatisfaction, returns, and lost revenue. Drop testers help identify weak points in packaging, enabling companies to reinforce them and ensure the product remains intact throughout the supply chain.

2. Compliance with International Standards

Various industries must comply with testing standards such as ISTA, ASTM, ISO, and others. Drop testing is a core requirement in these protocols. With Pacorr’s drop testers, manufacturers can easily meet these standards and confidently expand into global markets.

3. Cost Savings

Product returns, replacements, and warranty claims due to damage in transit can be costly. Investing in drop testing reduces these risks by allowing companies to refine packaging designs before full-scale production.

4. Customer Satisfaction

When customers receive products in excellent condition, it reflects positively on the brand. This leads to repeat business, positive reviews, and long-term loyalty.

Pacorr’s Drop Tester: Built for Accuracy and Reliability

At Pacorr.com, our drop testers are designed with the end user in mind. They are engineered to simulate realistic drop conditions and provide consistent, repeatable results. Whether you are testing a small electronic device or a bulky packaged product, our drop tester Price deliver precise data to help you make informed decisions.

Key Features of Our Drop Tester:

Adjustable Drop Height: Customize drop heights based on your product type and real-world scenarios.

Strong and Stable Base: Ensures safety during testing and minimizes external vibrations that could affect results.

Dual Arm Support: Securely holds samples for both flat and edge drops.

User-Friendly Controls: Easy to operate with minimal training required.

Durable Construction: Made from corrosion-resistant materials for long-term use in industrial settings.

Industries That Use Drop Testers

? Manufacturing

Electronics, appliances, and industrial tools need rigorous testing to avoid internal damage from impact. Drop testers are a key tool for pre-shipment inspection.

? Packaging

Corrugated boxes, cartons, and custom packaging solutions must protect their contents. Drop testing ensures the packaging is up to the task.

?️ Consumer Goods

Products like cosmetics, kitchenware, and home decor items are often fragile. Manufacturers use drop testers to confirm that packaging is protective without being wasteful.

? Electronics

Smartphones, tablets, and accessories face regular handling. Drop testing helps validate their resilience against accidental drops.

Types of Drop Tests You Can Perform

Pacorr’s Drop Testers allow for multiple test variations to simulate real-life conditions:

Flat Drop Test: To check how a product behaves when dropped flat on its base, top, or side.

Edge Drop Test: To evaluate the strength of package edges.

Corner Drop Test: Simulates impact on the most vulnerable parts of a box or product.

These different drop scenarios reveal structural weaknesses, enabling manufacturers to make improvements before launching or shipping their products.

Best Practices for Drop Testing

Use Actual Product Samples: Always test with the real product and packaging to get the most accurate data.

Test Multiple Angles: Don’t limit testing to one side—real-life drops are unpredictable.

Document Every Result: Maintain logs of drop height, product condition, and packaging status.

Perform Repeat Tests: Conduct multiple tests for consistency and statistical accuracy.

Simulate Real-World Scenarios: Use shipping and handling data to replicate the most likely drop conditions.

Why Choose Pacorr.com?

Pacorr.com is committed to quality and innovation. Our Drop Testing are trusted by industry leaders across the globe. Here's why:

Customization: We tailor testing machines based on your product dimensions and testing requirements.

Expert Support: Our team provides technical support, training, and guidance on best practices.

Affordable Pricing: High-quality machinery at competitive rates.

Global Reach: Serving clients in logistics, manufacturing, electronics, and beyond.

Final Thoughts

In today’s demanding markets, ensuring product durability is not optional—it’s essential. A drop tester from Pacorr.com gives manufacturers the insights they need to deliver safe, intact, and high-quality products. From improving design to minimizing loss, drop testing is the smart investment every business should make.

Discover our complete range of drop testers and testing instruments at Pacorr.com and take your quality assurance to the next level.