The increasing demand for tension control in web handling has positioned Banana Rollers at the forefront of industrial solutions, especially for applications requiring precise wrinkle elimination and web alignment. Across industries like plastic film, paper, textiles, and printing, manufacturers are turning to advanced roller systems to ensure high-quality output and operational consistency.

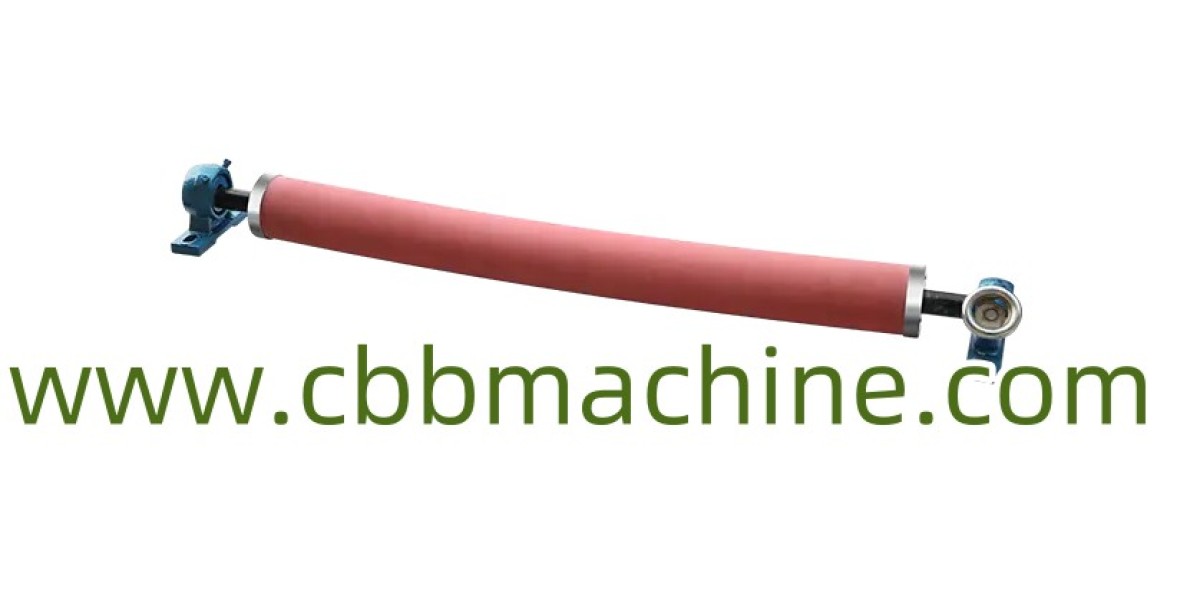

Banana rollers—also known as bowed rollers—are specifically engineered to apply lateral tension to materials running through production lines. Their distinctive curved (banana-like) structure gently stretches the material across its width, which helps eliminate wrinkles, align layers, and stabilize the web’s movement. These features are vital when working with flexible, stretchable, or multilayered materials, which are prone to misalignment and surface deformation.

The key advantage of using banana rollers lies in their non-contact stretching ability. Unlike mechanical edge guides or complex tensioning systems that can damage delicate surfaces, banana rollers work by altering the geometry of the web path. As the material moves across the bowed roller, it is evenly tensioned outward, naturally smoothing imperfections without applying excessive force. This makes them ideal for high-speed and precision-sensitive operations.

Customization also plays a critical role in banana roller performance. At cbbmachine, a range of customizable options is available to suit different industries and material types. Factors such as bow angle, roller diameter, surface coating, and shaft material can all be tailored to meet the user’s production environment. For example, anti-corrosion coatings are used in humid conditions, while anti-static features are added for sensitive electronic film applications.

Durability and maintenance are other areas where banana rollers shine. When manufactured using high-quality bearings and balanced components, these rollers offer long service life and minimal downtime. Cbbmachine’s engineering team ensures that each roller is precision-balanced to reduce vibration and wear, increasing the lifespan of both the roller and the machinery it serves. Maintenance intervals are extended thanks to sealed bearing designs and robust construction.

Moreover, integrating banana rollers into automated production systems improves efficiency. By maintaining consistent web tension, these rollers reduce waste caused by misaligned printing, tearing, or folding. They also support higher operational speeds, enabling companies to meet production targets without sacrificing quality. In high-throughput industries, even small gains in alignment accuracy can translate into significant cost savings over time.

Banana rollers are also gaining popularity due to their compatibility with modern web guiding systems. They can be used in tandem with sensors, actuators, and smart controllers for real-time adjustments. This synergy between mechanical design and intelligent control enhances both process reliability and product uniformity.

In short, the banana roller is more than just a supporting component—it is a key element in driving industrial performance forward. With continuous innovation in materials, coatings, and customization, banana rollers will continue to play a crucial role in the future of precision web handling.

To explore customizable banana roller solutions designed for your unique production needs, visit:https://www.cbbmachine.com/product/banana-roller/customizable-banana-roller.html